Longxiang Group

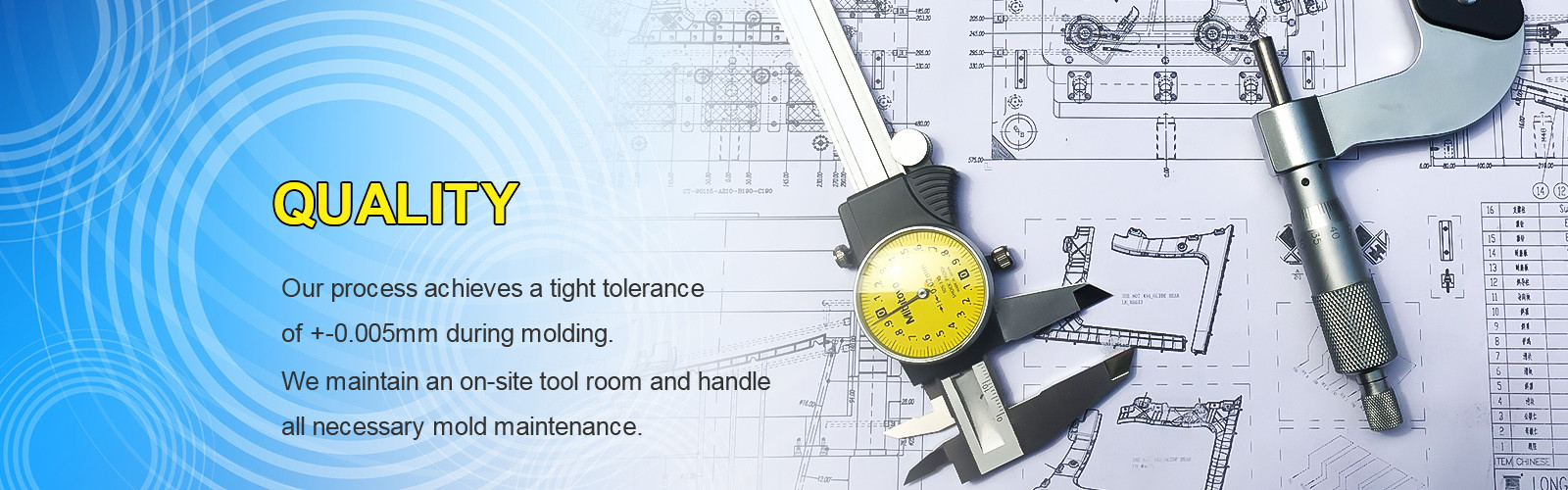

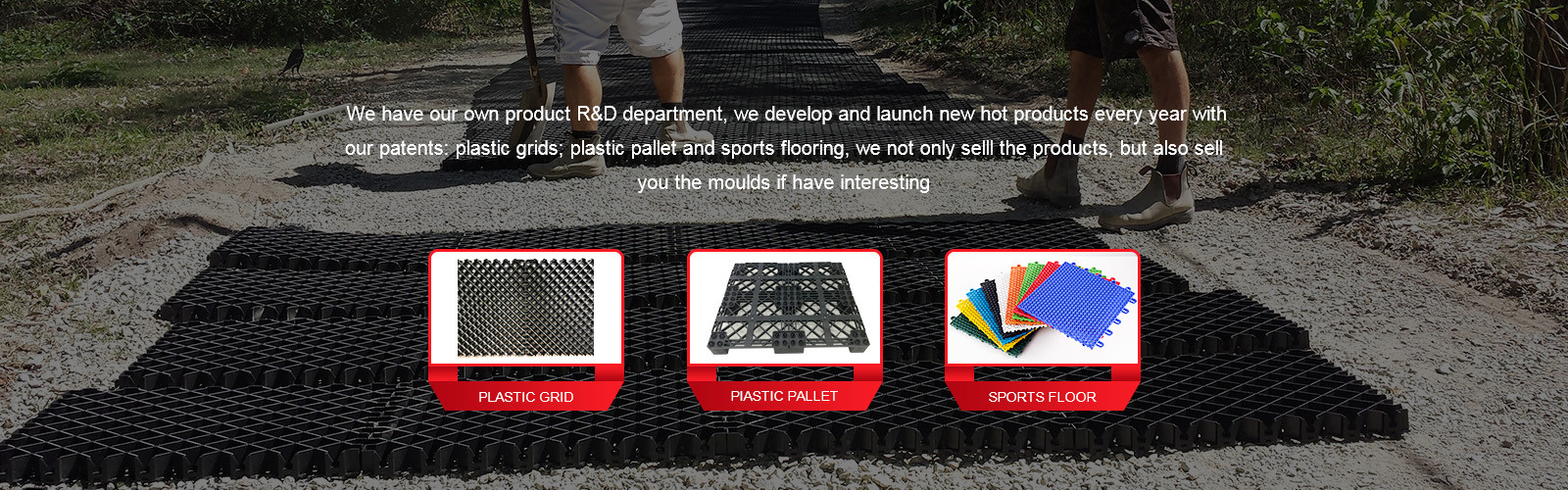

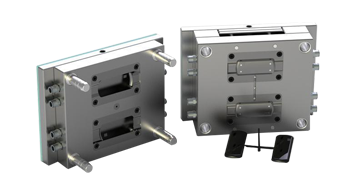

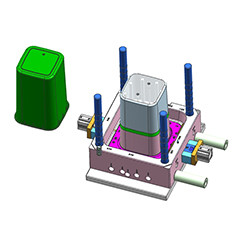

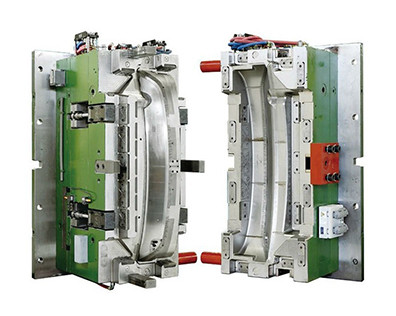

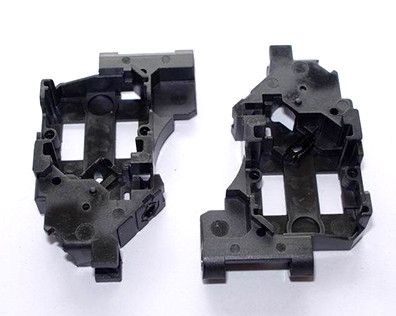

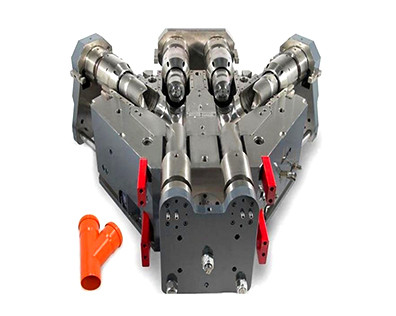

Longxiang Group is a plastic injection molder in Guangzhou Since 1998, We manufacture all sizes, precision-engineered, injection-molded components used in a wide array of applications in diverse industries, including automotive, electronics, medical, consumer appliance, office furniture, telecom, business equipment, and recreational vehicle and boating markets.

We offer customers full-service manufacturing solutions that include design, engineering, mold making, production – including insert molding, overmolding and encapsulation of components – value-added assembly, inventory management, and distribution.